CFDLab has a rich background of many years in CFD engineering simulation for some industries of different sectors. Here below are reported some cases studied in the past.

|

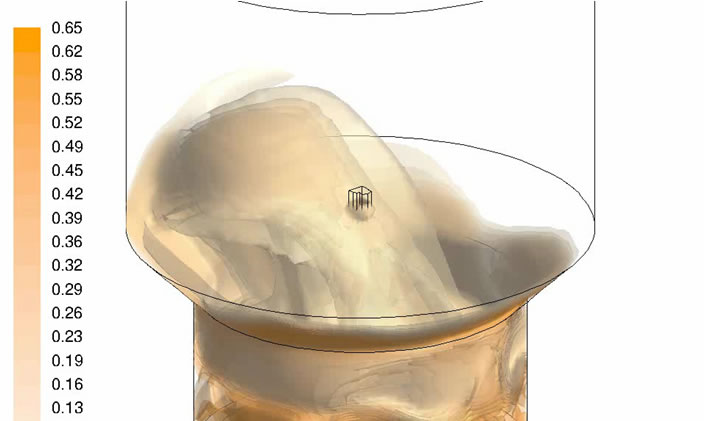

Analysis of some scenarios for incidental diffusion of natural gas in atmosphere.The aim of this study was to evaluate different incidental scenarios to verify what really happend. In figure is represented the flammable cloud. |

|---|---|

|

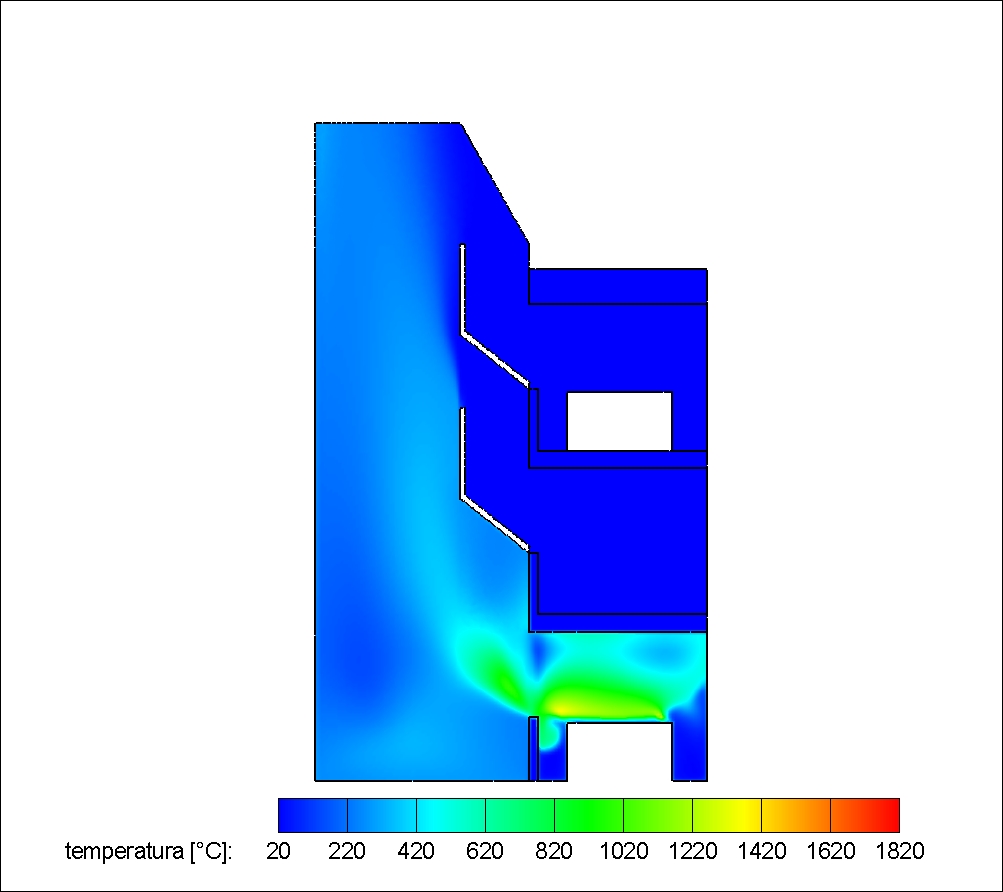

Thermal Analysis of a domestic oven. Simulation of a domestic oven to characterize the efficiency of the system and improve the design in term of material insulation, radiative properties of the cavity and recirculation system. The image represents temperature distribution field inside the cavity. |

|

Autoclave thermal analysis; Autoclave analysis to uniform the flow field at the inlet of the oven. Different geometries are simulated and also unsteady analysis were done to improve thermal treatment.

|

|

Fluidized bed for send regenration.Analysis of 3d plant to design and verify the system. Send is modelled with eulerian-eulerian approach and also combustion is computed. The image represent the solid-phase (sand) during fluidized-bed recirculation. |

|

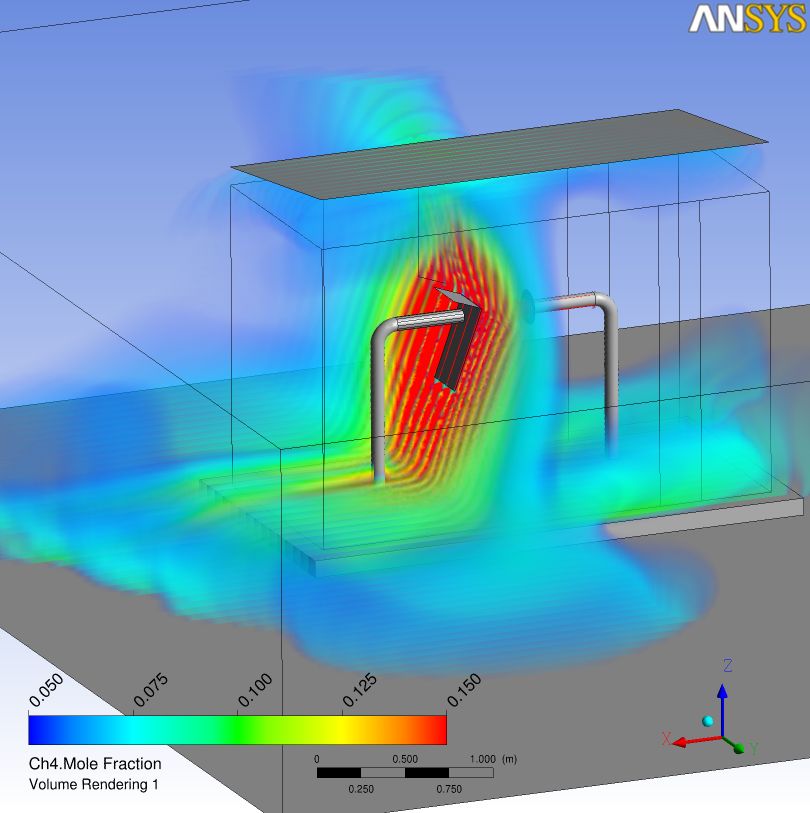

CFD modeling of a domestic burner.Evaluation of the air/fuel ratio at different operating conditions. Image represents methan mass fraction. |

|

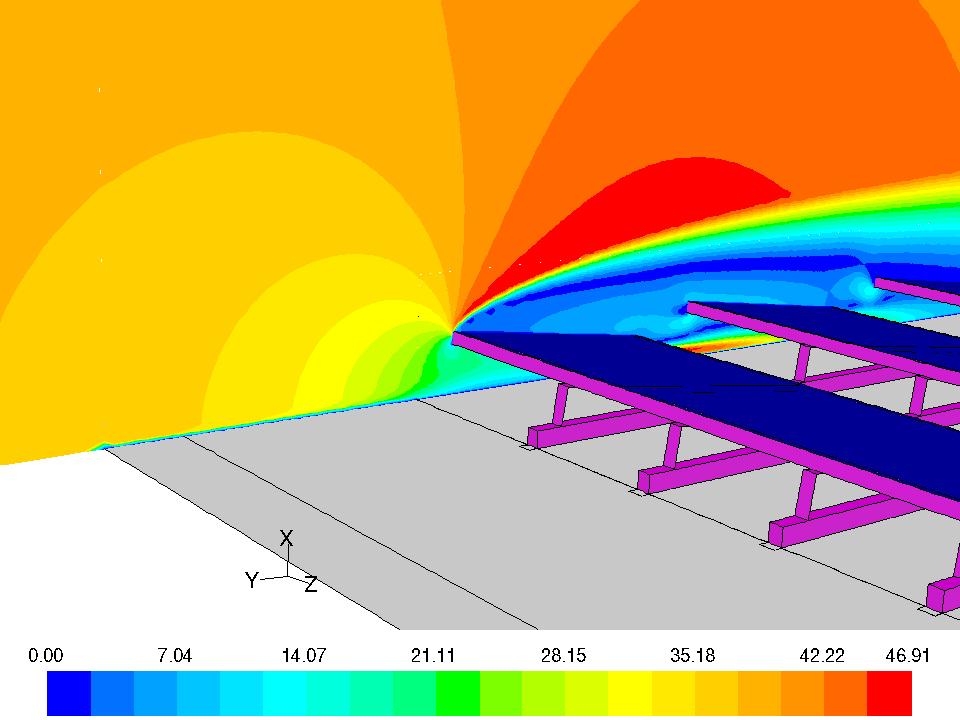

CFD modeling of wind load on PV panels on flat roofs.Optimization of the support frame to reduce wind load effects and so reduce or remove the blocks to anchor the panels to rhe roof. |

|

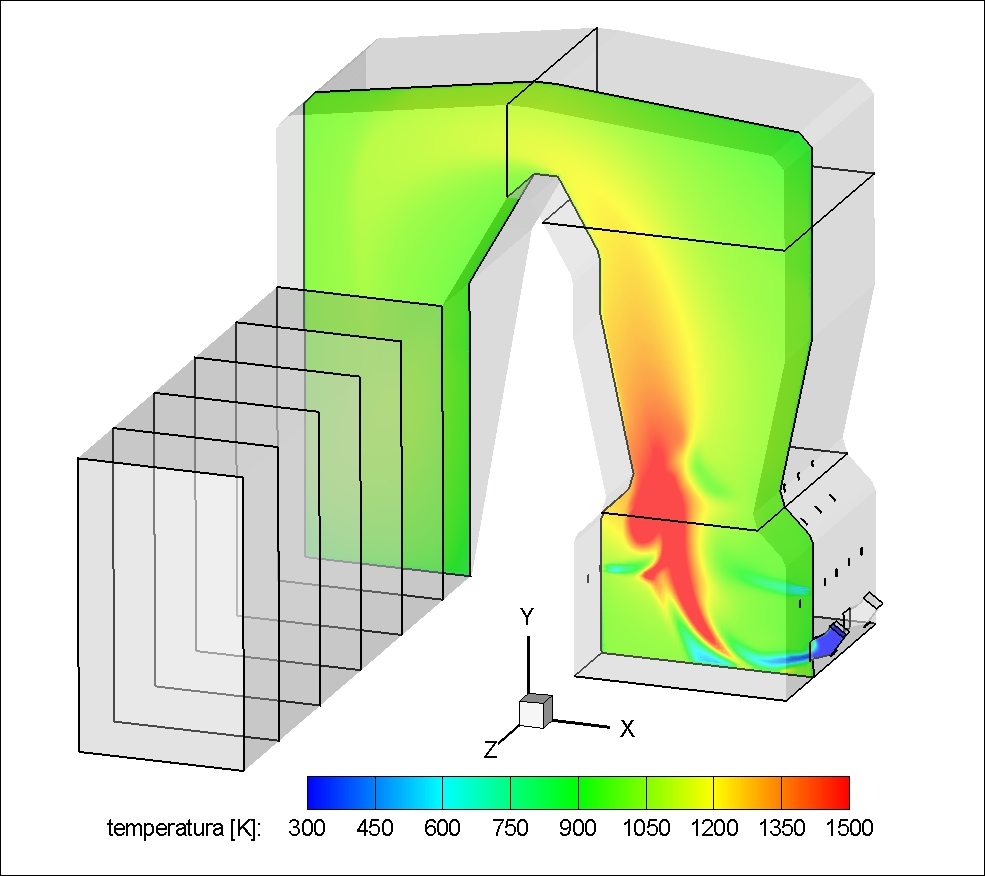

Full 3D simulation of Waste for Energy plant (CDR)Analysis of emission limits and improvement of the geometry to increas heat exchange. The waste fluidized bad is modeled with DPM approach. |

|

Accidental Fire in a parking garageStudy and simulation of ventilation system in different parking garage to verify the ventilation that was designed to work in natural convection. |

|

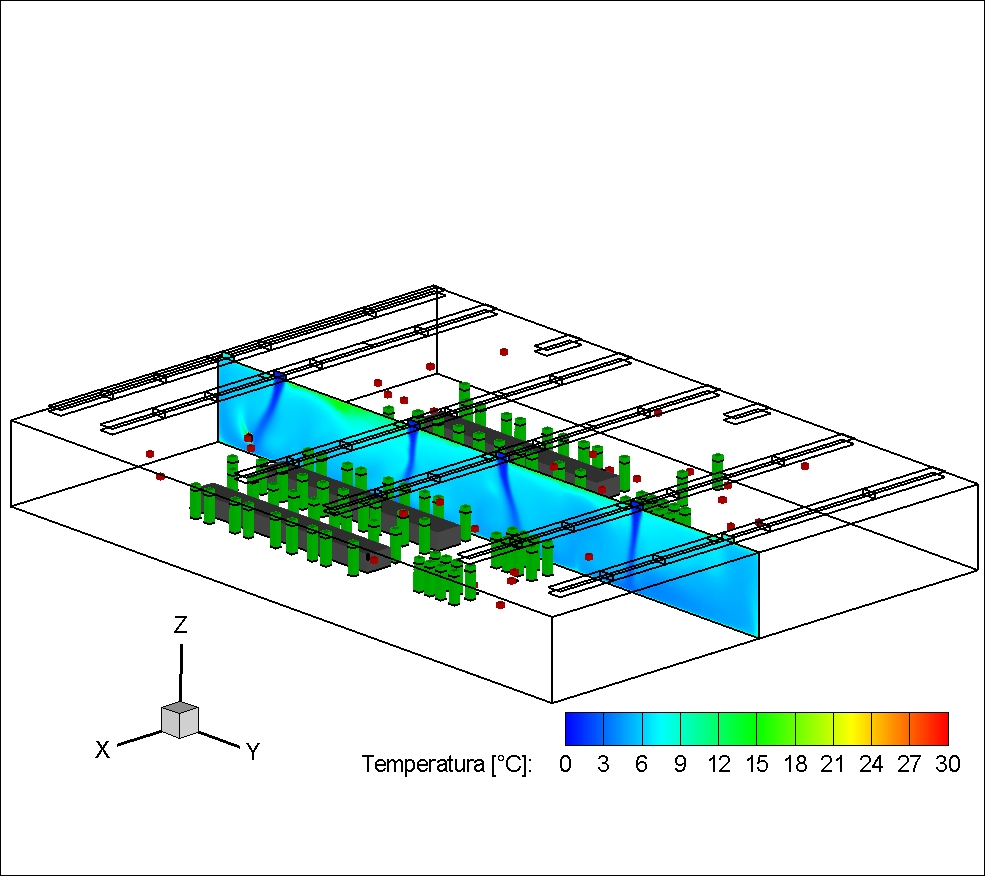

Simulation of ventilation system in a food industryStudy of air velocity, temperature and humidity to verify comfort limit imposed for workers. |

|

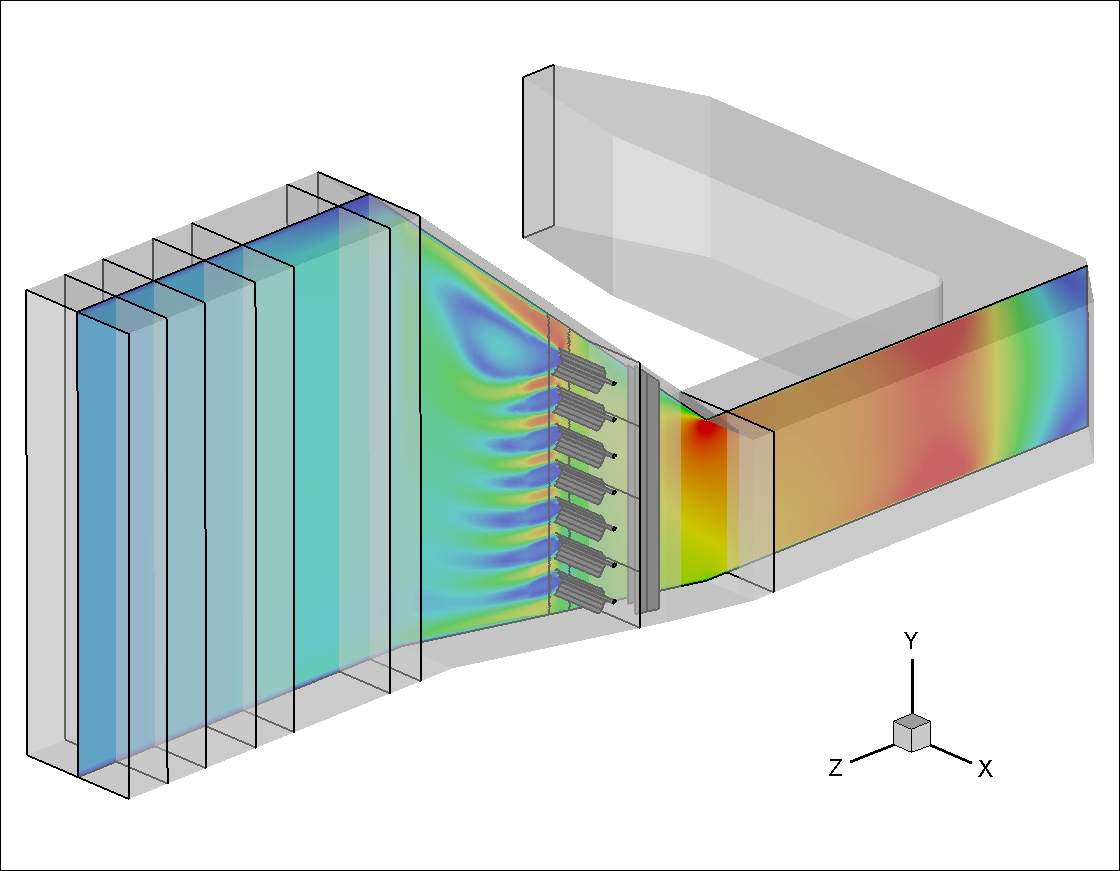

Fluid dynamic simulation of an HRSG with post-combustion.Optimization of distributive grid upstream the combustors to uniform the feeding improving methan reaction. All the operative condition were verified. |

|

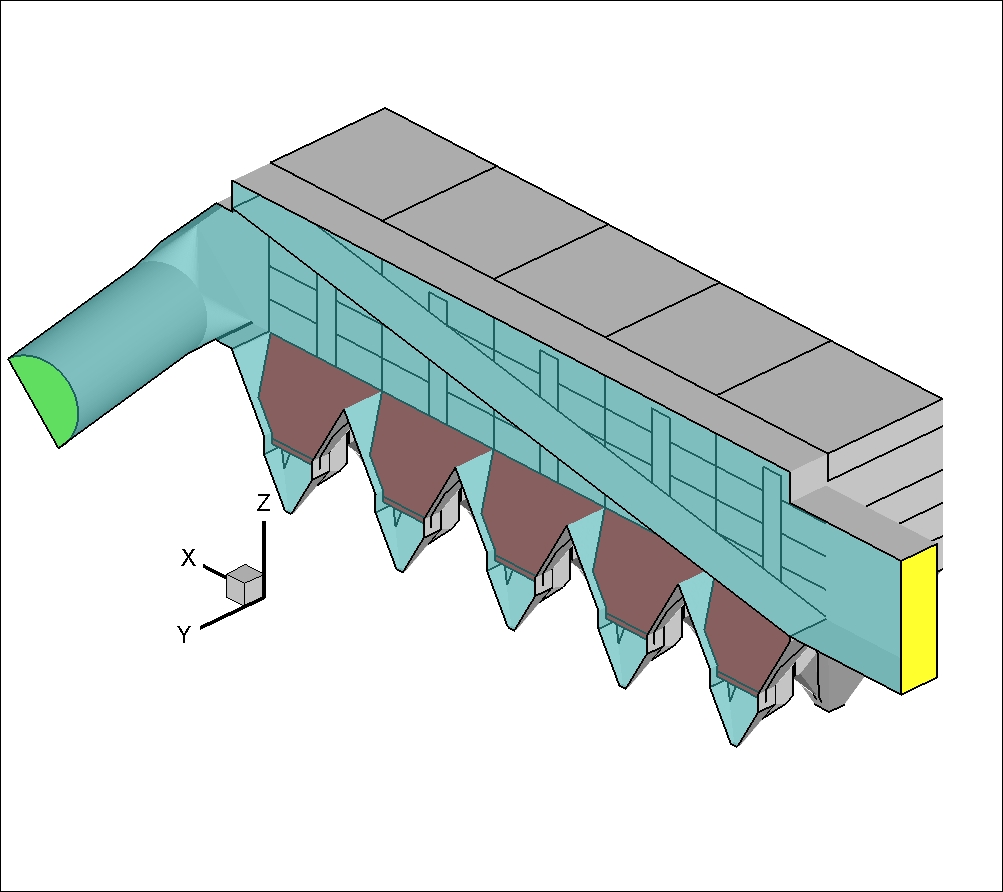

Improving evaporator efficiency in an HRSG systemEffectiveness of gas baffle design to prevent by-pass HP evaporator has been analized trough a CFD in order to detect the real effectiveness of the heat exchange in the coil with the present module and gas baffle design. |

|

Optimization of bag filters.The study aims at understanding the fluid dynamic behaviour for a dust remover characterized by bag filter technology |

|

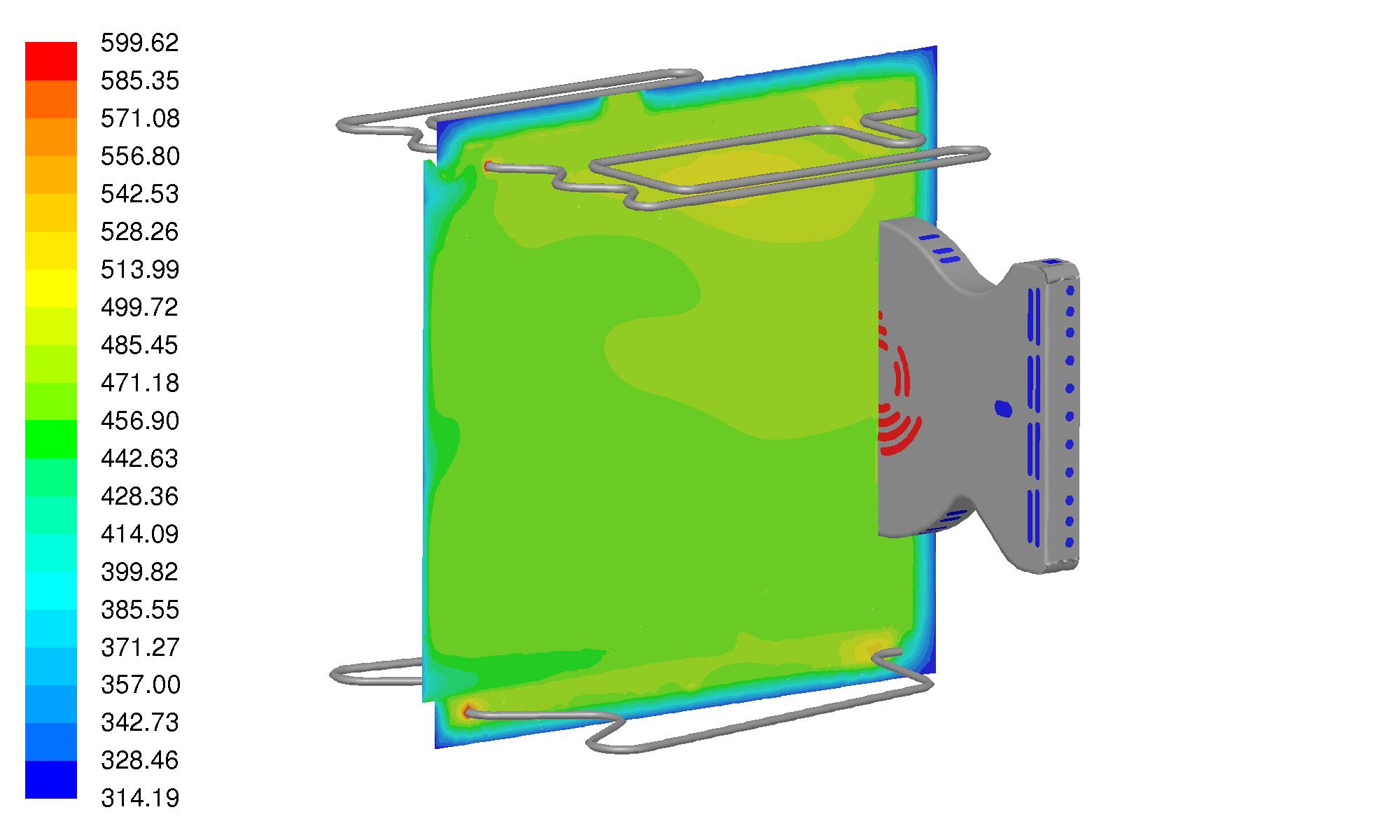

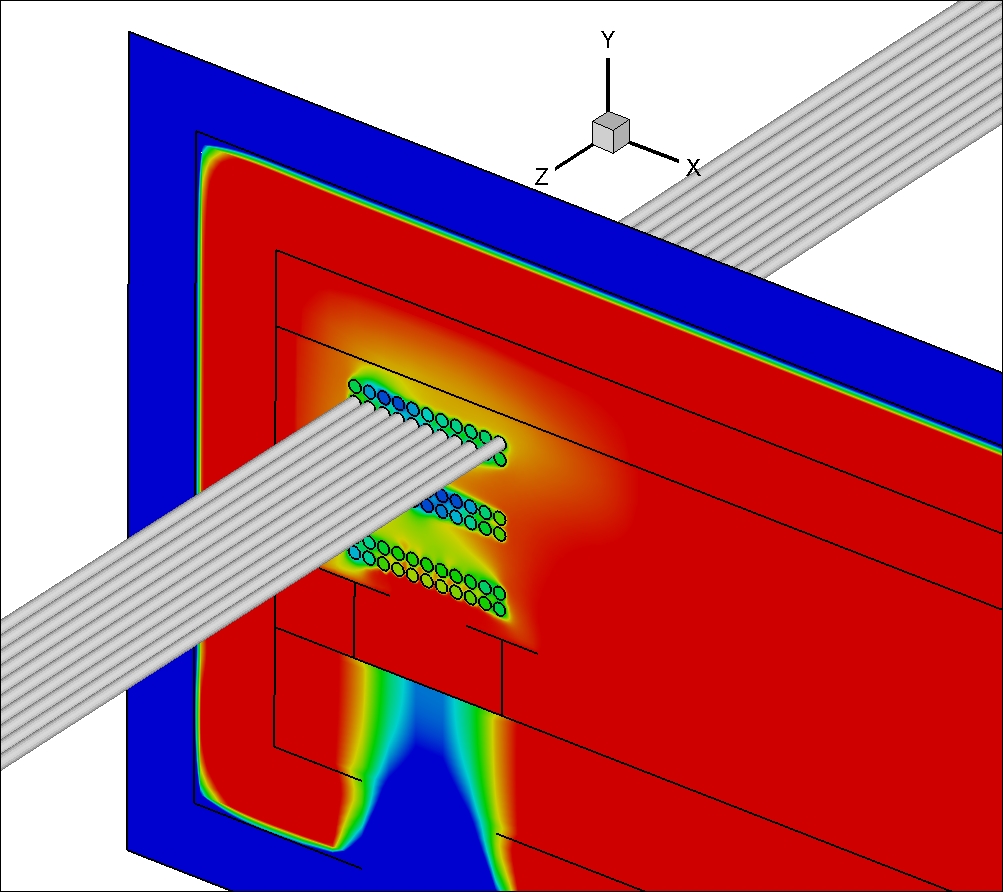

Autoclave CFD analysis:Thermal field distribution. The goal of the analysis is the control of the temperature uniformity during soaking and during ramping of a plant for heat treatment of Double Pancakes for toroidal Coils of ITER Project |